%20(4).jpg)

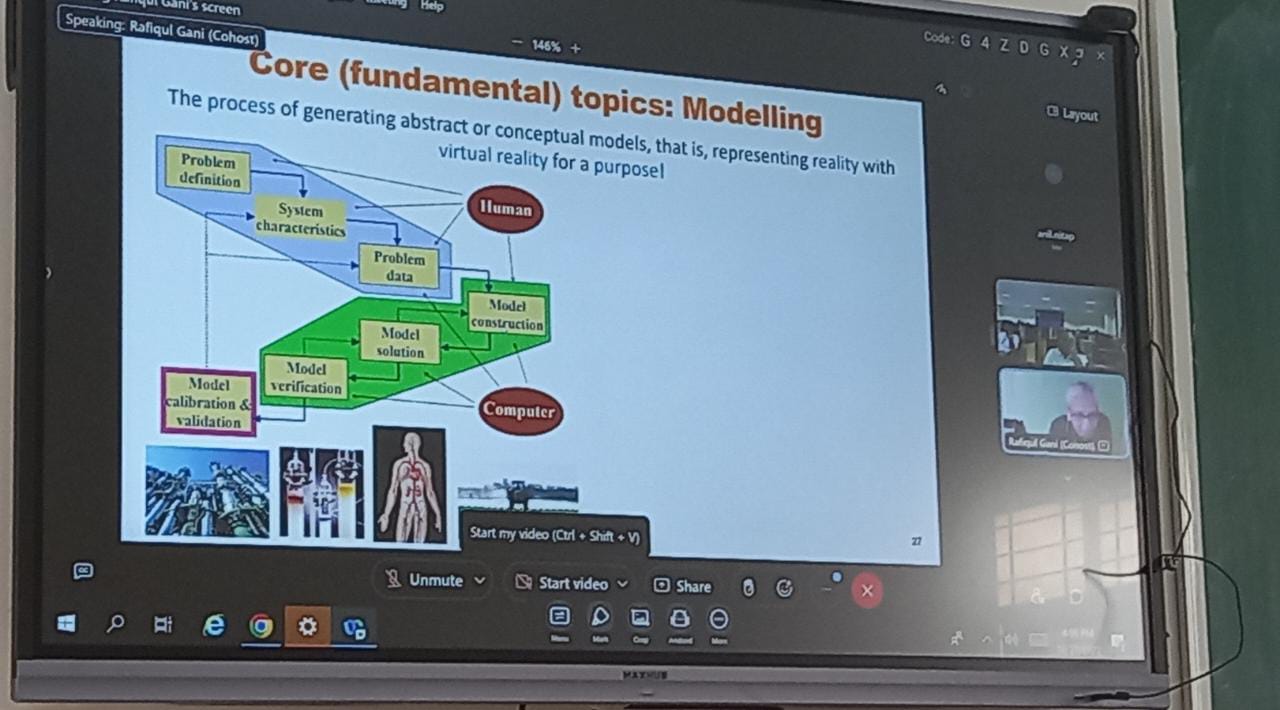

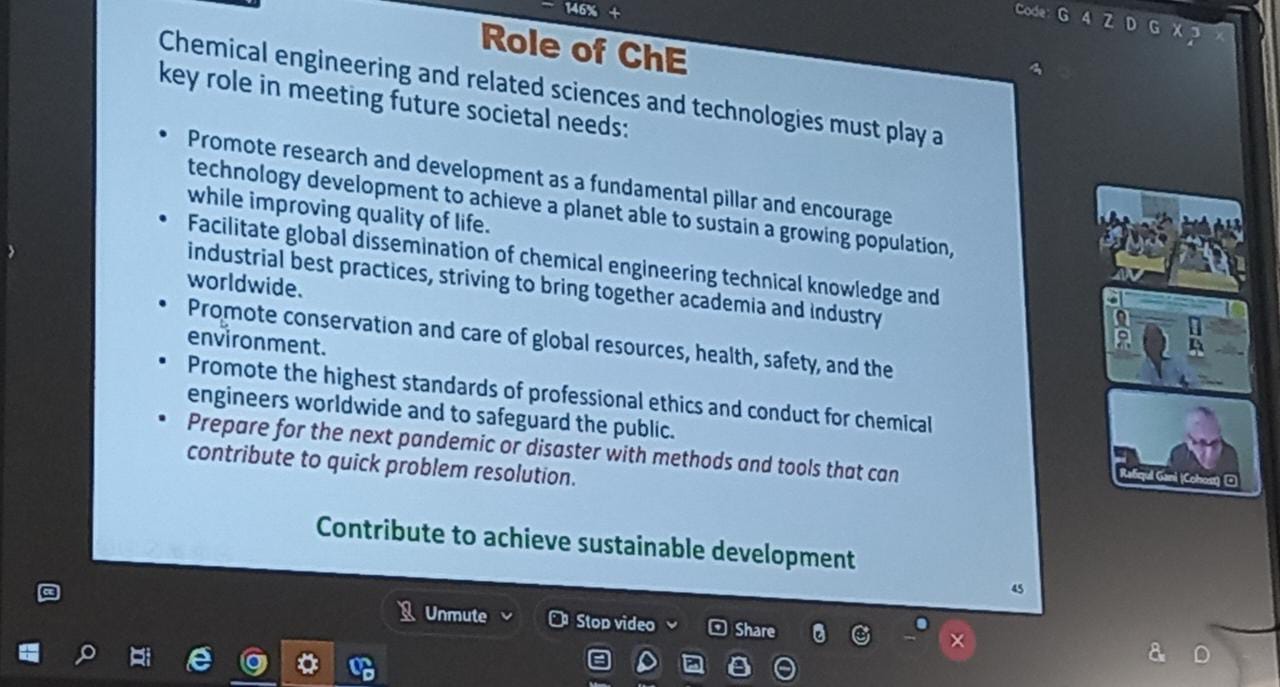

Process Systems Engineering (PSE) is a multidisciplinary field that deals with the design, optimization, control and management of complex chemical processes. PSE aims to improve the efficiency, safety, reliability and sustainability of chemical processes by applying mathematical models, computational tools and engineering principles. PSE has many applications in Chemical Engineering, such as process synthesis, process intensification, process integration, process simulation, process control and process operations. In this lecture, we will introduce the main concepts and methods of PSE and illustrate how they can be used to solve various problems in Chemical Engineering. This was an informative lecture where IICHE has explained on Process Systems Engineering and its application in Chemical Engineering.

The discussion will center on process or concept ideation, process or product innovation or development, and technology transfer to industry for commercialization. Energy conservation is a worldwide concern for the long-term viability of urban and rural societies. This symposium will encourage innovation, process development, and technology commercialization, as well as the exchange of thoughts and ideas that will aid in learning.

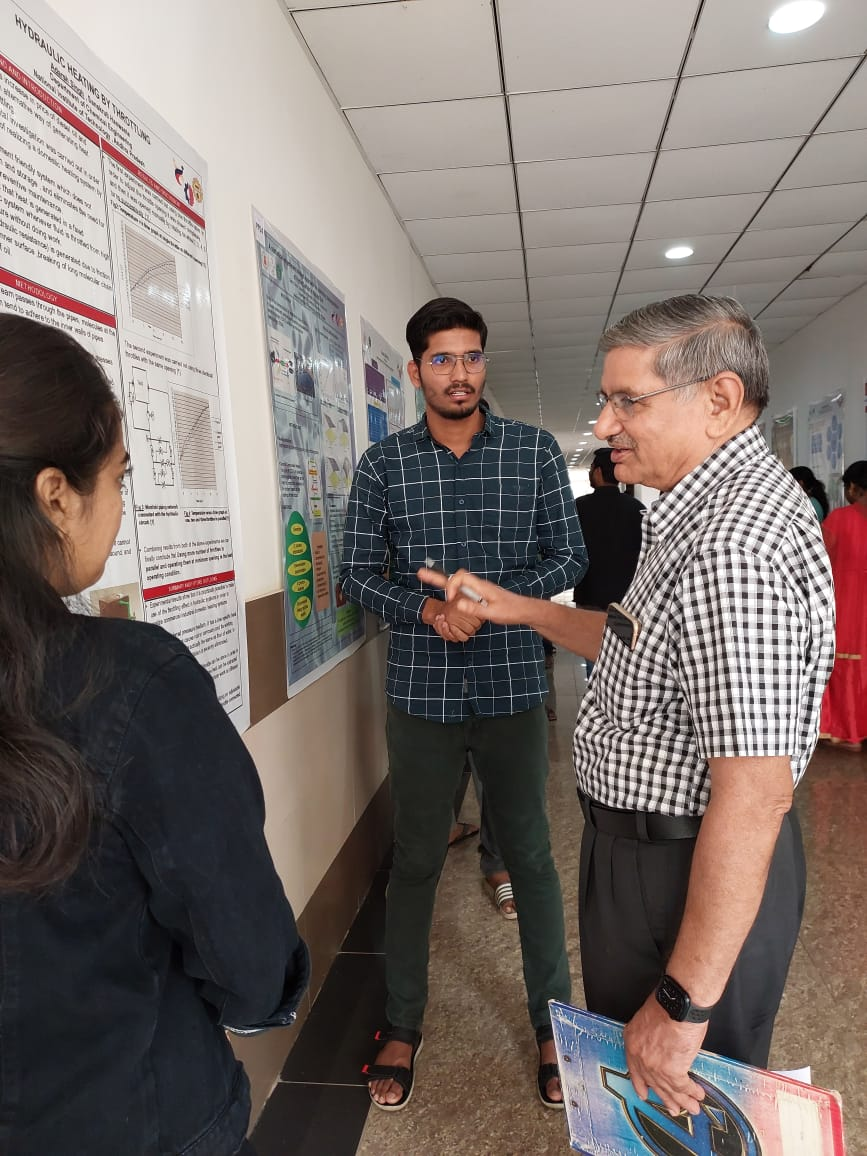

We conducted these two events as part of our college's technical fest, which was called Vulcanzy 2023. The events were a great success and attracted a lot of students from all over. We had a huge turnout and the students were very enthusiastic about the topics we discussed. We look forward to planning more such events in the future.We had a great turnout of participants from various departments. The enthusiasm and energy of the students made the fest a huge success.

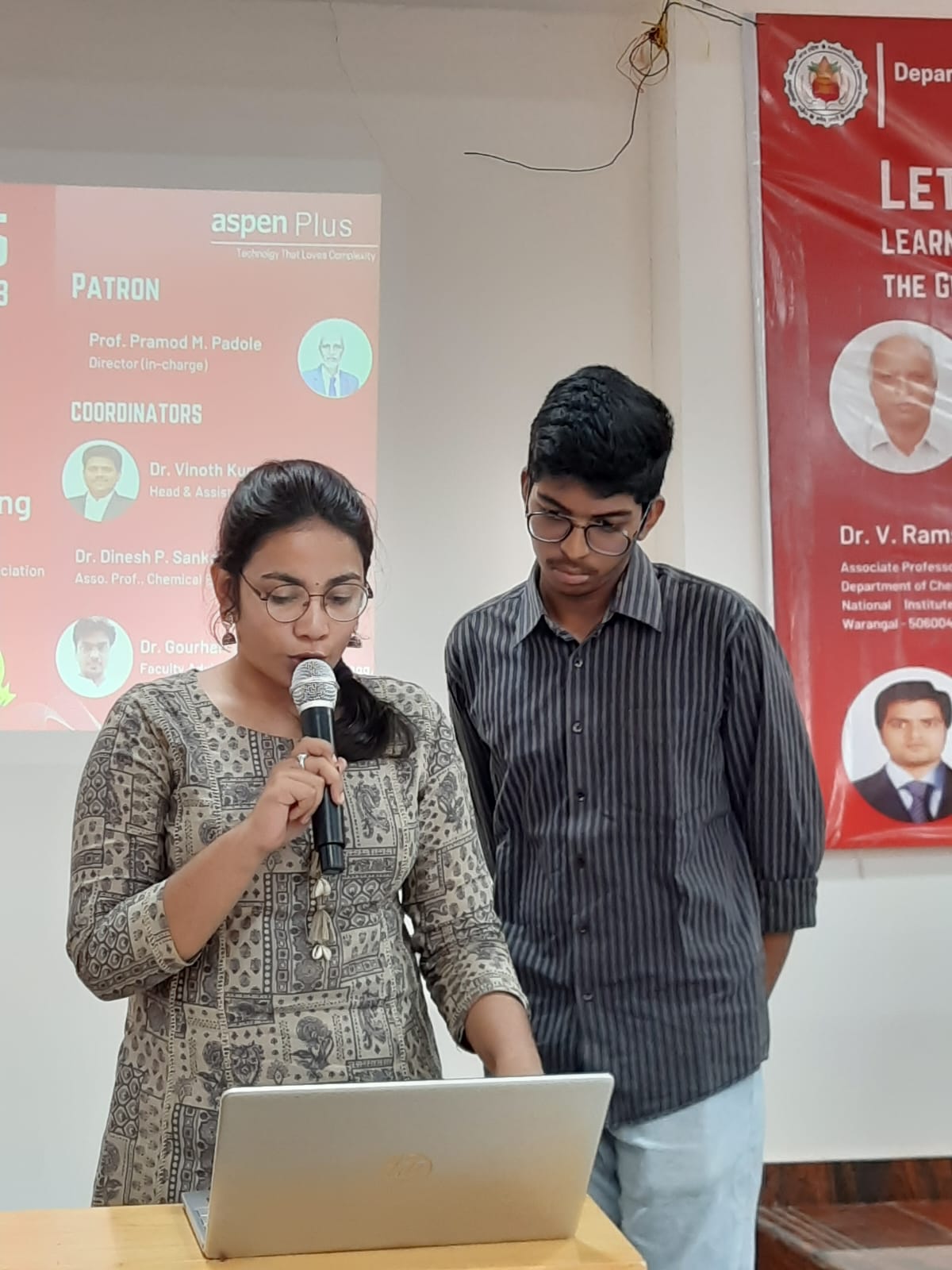

An interactive two-day workshop by Dr. Saratbabu Anne and Dr. V. Ramsagar to provide hands-on practice using the software used in chemical processing industries to simulate unit operations.Introducing Aspen Plus and its features Building a simple simulation using Aspen Plus for industrial unit operations (e.g. absorption and distillation columns). Create process flow diagrams in AspenPlus Enter and manipulate data in AspenPlus Develop and simulate process models in AspenPlus Analyze simulation results and draw conclusions. Workshop (Hands-on training in modeling and simulation of chemical problems) Furthermore, learn to optimize process designs, interpret and analyze material and energy balances, and understand the impact of design parameters on system performance.